A Few Words About Us

External corrosion groups from various operators are working with industry stakeholders to develop a unified approach to corrosion monitoring and mitigation. The goal is to minimize and effectively manage external corrosion risks. This approach is referred to as "Integrated External Corrosion Management (IECM)".

Introduction to IECM

Pipeline systems are vital for transporting oil and gas, but they can be subject to corrosion. This can lead to leaks and other safety issues. To address this, many companies are turning to data analytics to help manage corrosion threats.

The Integrated External Corrosion Management (IECM) approach uses extensive historical data, environmental data, and advanced analytical tools to identify potential problems and prevent them before they occur. This helps improve safety and reliability, as well as operating efficiency.

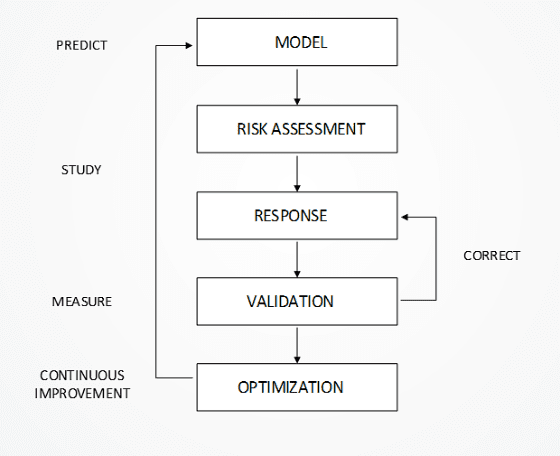

The IECM program uses a development cycle with four phases: predict, measure, study/correct, and continuous improvement.

Risk Reduction

In order for a pipeline system's external corrosion levels to be considered acceptable, a technician is traditionally required physically travel and take electrical measurements at various test points across the network. This process presents a significant risk for the personnel who cover thousands of miles of pipelines. "With advancements in technology and expertise in the decades since the traditional method was formulated, our team believes there must be a more efficient way."

The risks associated with field surveys (including established environmental risks) as well as human logistics risks (driving and other modes of travel) often contribute significantly the total risk factor.

IECM Approach

As the world progresses, so too does the way we manage our resources. The Engineered, Integrated Approach to External Corrosion Management (IECM) is a novel approach that is gaining traction in the industry. This method seeks to capitalize on an organization's internal expertise by integrating subject matter expert (SME) groups in external corrosion protection, pipeline integrity, and reliability.

The goal of IECM is to improve safety and reliability of the pipeline system, along with increasing operating efficiency. This is accomplished by utilizing extensive historical data and advanced analytical tools such as diagnostics and modeling. This approach is consistent with general industry trends which aim to make better use of available information and resources.

This method offers a more holistic perspective on corrosion management, and has the potential to revolutionize the way we protect our pipelines from external damage.

The IECM program utilizes a development cycle with four general phases: predict, measure, study/correct, and continuous improvement. This framework will help ensure that potential corrosion problems are identified and addressed in a timely and effective manner.

Expected Benefits

The IECM program is designed to improve the reliability of pipelines, reduce the risk of damage from stray currents, and improve the efficiency of resource allocation for external corrosion protection. This will be accomplished in part by identifying and focusing on key test points that are representative of sections of pipe rather than placement at distances of one or two miles, reducing field presence associated with compliance with AMPP (NACE) criteria, and reducing replacement and maintenance costs associated with maintaining CP systems.

Continued Improvements

The IECM team is continuing its work to refine and develop the model in several ways. These include: Performing validation studies to confirm model predictions; Quantifying error(s) inherent in the model and incorporating into risk assessment; Confirming statistical methodologies for model alignment and data gap analyses; Utilizing case study results to determine response protocols and corrective actions;

Incorporating mechanistic modeling into the selection of response protocols; Developing optimization processes. “Once the technical foundation for the program has been fully developed and validated, we plan to further integrate the various stages into a machine learning process process to minimize assessment and response times. Once fully developed and vetted, the IECM approach will allow our organization to improve efficiencies in operations while maximizing environmental and public safety.