IECM Program is a Iterative Method for Control and Continual Improvement

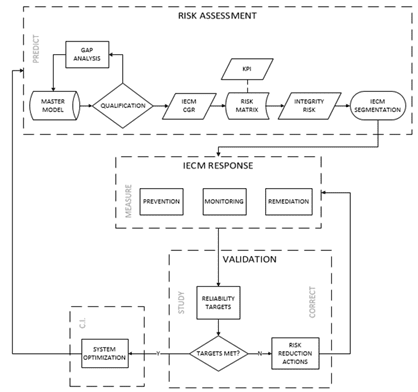

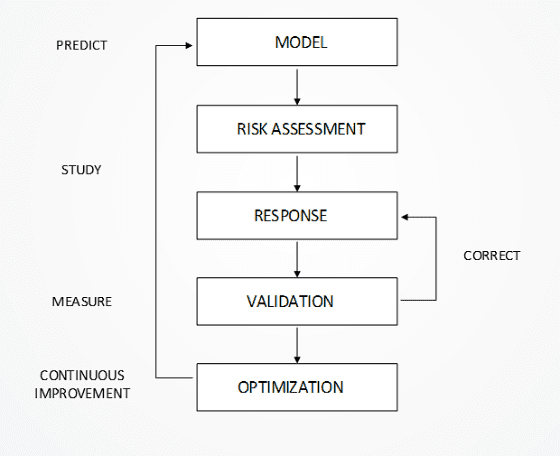

The IECM program, or the Integrated External Corrosion Management program, is an iterative method for the control and continual improvement of processes related to external corrosion management in pipelines. The program consists of five phases:

Predict Phase: This phase begins with a robust risk assessment aimed at quantifying relative corrosion risk across the pipeline network. The prediction phase begins by reviewing the mechanistic model to determine its suitability for an integrated approach.

Measure Phase: In this phase, various IECM response protocols are defined and deployed in proportion to the determined level of risk. These protocols include activities such as external corrosion direct assessment, installation of new cathodic protection systems, upgrades to existing cathodic protection, and increased surveillance.

Study/Correct Phase: This phase determines if reliability targets are being met because of the responses outlined in the Measure Phase. If the segment meets these targets, continuous improvement activities may begin. If targets are not met, additional risk reduction activities must be initiated in the short-term.

Continuous Improvement Phase: In this phase, IECM segments that have met reliability targets are candidates for optimization of external corrosion protection system operation according to the IECM reliability category as defined above.

Validate Phase: This phase is conducted to determine if the implemented optimization measures have improved the pipeline's reliability targets. If the pipeline meets the targets, the process starts again with the Predict Phase. If not, the pipeline goes through the corrective actions and subsequent validation phase until the targets are met.

By following these five phases, the IECM program ensures the safety and efficiency of pipeline operation by providing a systematic approach to external corrosion management.

IECM Process

Learn more about the IECM Program